Contact

0769-89915990

MAIN PRODUCTS

From raw materials/equipment/processes to testing with almost strict standards

Specializing in the production of high-end headphones, chargers, massagers, new energy vehicles, electronic cigarettes, entertainment audio plastic parts

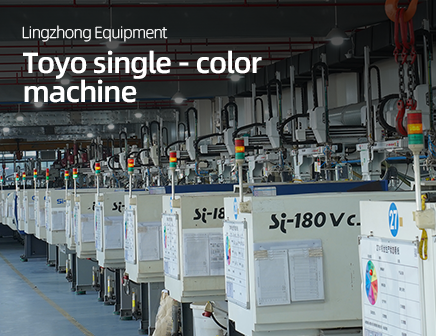

LINGZHONG EQUIPMENT

Advanced equipment and excellent technology

The company has a full set of industry-leading mold making, injection molding, precision carving, laser carving, pad printing and testing equipment, more than 100 professional and technical personnel, process technology and standards have reached the advanced level of the industry, and has a young, high-quality, shrewd and strong management team The team has passed the ISO9001:2018 quality system certification; monthly new mold production capacity is 40 sets, imported two-color and single-color injection molding 46 sets, and plans to increase the new mold production capacity to 50 sets/month and the injection molding machine to 80 sets within the year , Add spraying process to meet customers' increasing production capacity and process requirements, and improve customer satisfaction. Appraised as "Guangdong Province Contract-abiding and Credit-Reliable Enterprise".

learn more

Continuous technological innovation and capacity upgrade

Specializing in the production of high-end headphones, chargers, massagers, new energy vehicles, entertainment audio plastic structural parts

Lingzhong's 4 major strengths, let you choose worry-free

1

Strong strength, one-stop service

2

Advanced equipment and excellent technology

3

Standardized management, punctual delivery

4

Good quality and low price, high quality after-sales

LATEST NEWS

Regularly update Lingzhong and industry information

01/13

2022

Founded in 2015, Liesheng Technology has grown into a global consumer electronics brand enterprise with with its products being sold in more than 100 countries and regions worldwide and serving tens of millions of users. With the vision of "Redefine Intelligent Life", Liesheng continues to explore intelligent life scenarios and is committed to improving everyone's life quality via data. As a fast-growing and highly creative global enterprise, Liesheng always views technological innovation as the core drivers of its business, with R&D personnel accounting for 60% of its employees. It has two R&D centers, which are located respectively in Shenzhen and Dongguan. And it will build Liesheng Southwest Headquarter in Chongqing Science City to gather excellent scientific talents in various fields.Liesheng has successfully built Haylou, a consumer electronics brand, and has continued to explore and innovate in healthcare, IOT, and big data in order to build a brand new intelligent and healthy life for its consumers.

10/22

2021

High precision plastic mold processing steps

Driven by the drive system, the screw conveys and compacts the material from the hopper. Under the combined action of the heater, screw and barrel outside the barrel, the material is gradually melted, and the material is gradually melted at the head of the barrel. A certain amount of molten plastic has accumulated in the part. Under the pressure of the melt, the screw slowly retreats. The retreat distance depends on the amount required for one injection of the metering device. When the predetermined injection volume is reached, the screw stops rotating and retreats

10/22

2021

What to pay attention to in injection mold

The shrinkage coefficient of each material is different, and the plastic mold must have a reasonable shrinkage rate. The plastic mold must have sufficient rigidity, otherwise it will deform during clamping and holding pressure, causing "flash". If the product is ejected while opening the mold, the ejector page of the injection molding machine can be set (but some injection molding machines do not have this function).

learn more

Hotline:0769-89915990

Fax:0769-89915990

Mail:yaoguirong@lzmuju.com

Address:No. 38, Daohou Road, Daojiao Town, Dongguan City, Guangdong Province

Mobile phone line :13809276153

Copyright © 2021~2024 东莞市凌众精密模具有限公司